Custom antenna design service

Our antenna team has developed custom antenna design solutions for a broad range of devices, from tiny Bluetooth headsets to the complex 5G antenna systems used in smartphones and smart watches.

Innovation

Our core strength is our innovative personnel, who combine long experience with eagerness to learn new. We believe that collaborative teamwork creates the ideal environment for innovative antenna solutions. Custom antenna design requires the right skills and tools.

Speed

Modern antenna design involves hundreds of simulation rounds. Efficient simulation-assisted design methods allow us to tune and evaluate multiple antenna solutions simultaneously. This means we can choose the ideal technology for your product.

Accuracy

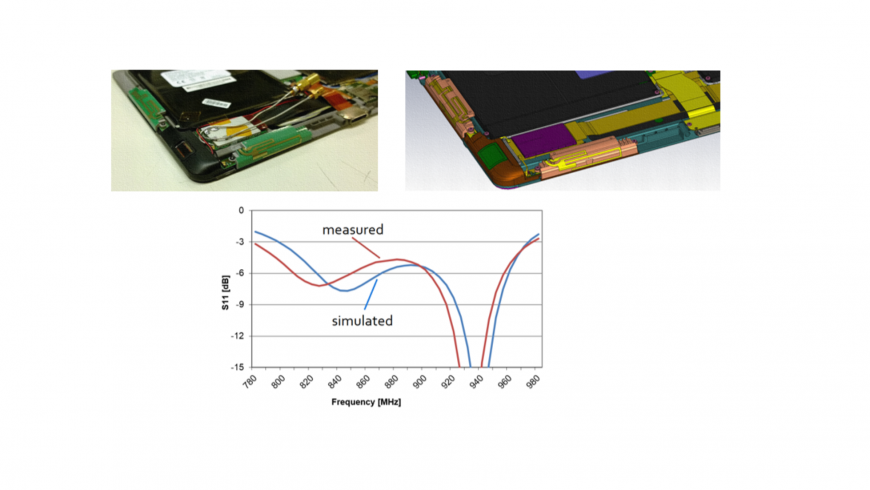

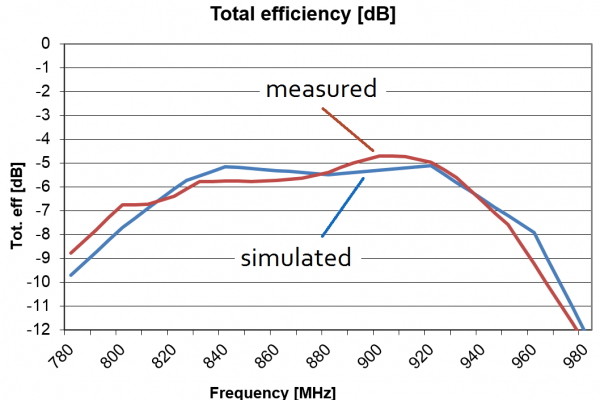

With the right tools, correct modelling and skilled designers, we produce simulation results that correspond superbly with the device measurement.

Over-the-Air Requirements

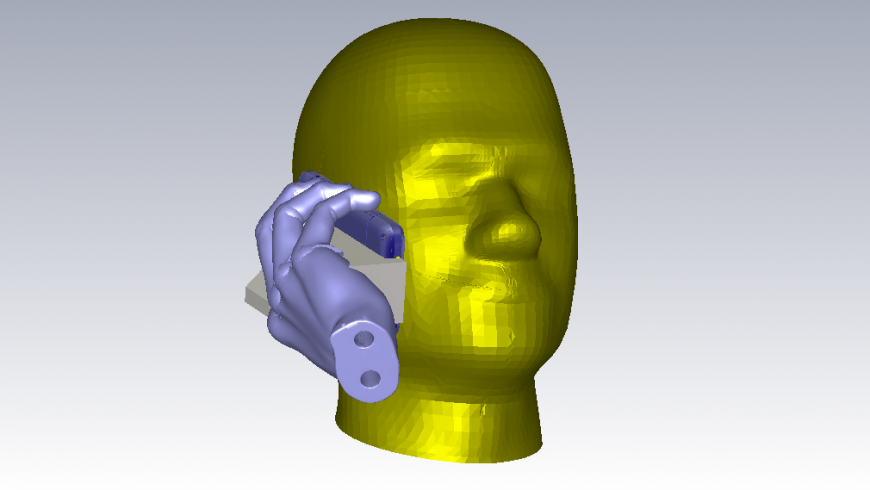

Convergentia simulation tools allow the OTA performance of a device to be estimated early in the product development process. We design custom antennas so that they fulfill operators’ requirements and comply with SAR regulations.

Partners

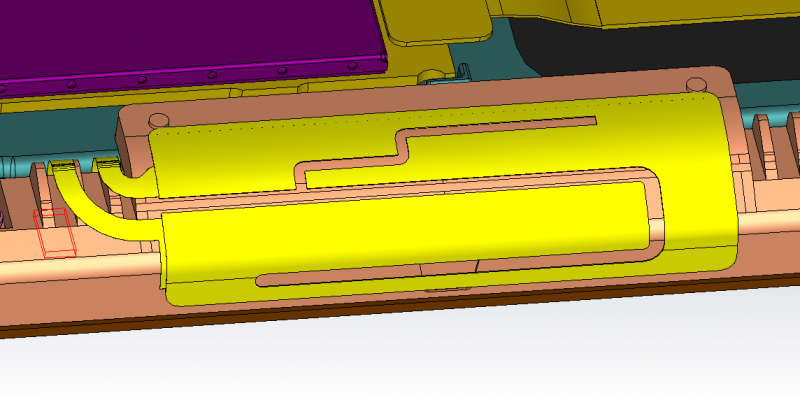

Through our manufacturing partners, we are able to offer the optimal antenna manufacturing technology to manufacture our custom antenna design. The technologies we have available range from simple flex film antennas to the newest printable 3D antennas.

To complement our own Satimo-based antenna measurement system, our partners work with us to perform official OTA certification measurements for cellular, Wi-Fi and GPS, as well as SAR compliance testing. We have an insider’s view of state-of-the-art impedance matching solutions and we use them extensively in our designs. Our network of partners gives us access to the very latest switch, tuner and passive component technologies.

Simulation Accuracy

When simulations are carried out properly, it cuts the number of prototype rounds and the overall device development time. There are two reasons for this: Firstly, there is no need for mechanical or PCB changes due to antenna performance issues. Secondly, because all the antennas work after the build, other areas can be tested without the need to wait for the antenna designers to get the antennas working first. Getting good correspondence between simulations and measurement results is not trivial. We make use of our experience and expertise to model the critical parts with sufficient precision while keeping the simulation time reasonably short. With the help of simulation tools we are able to create the best possible custom antenna design for your needs.

Tools & Methods

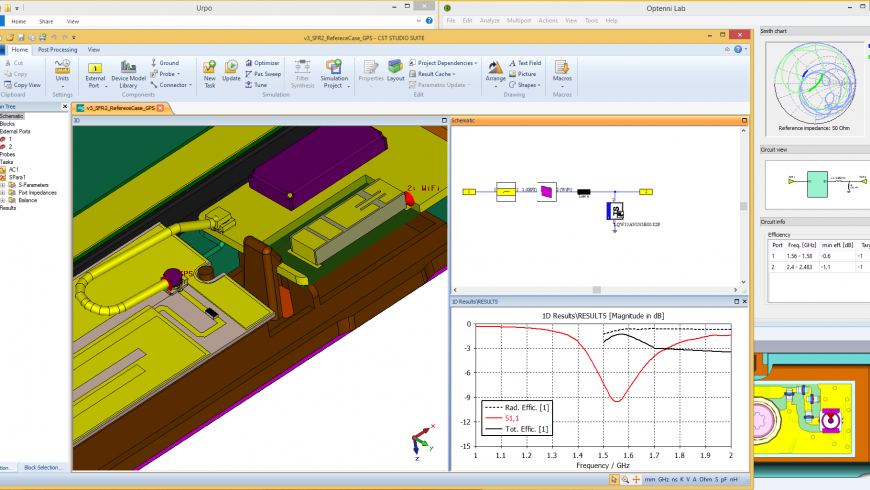

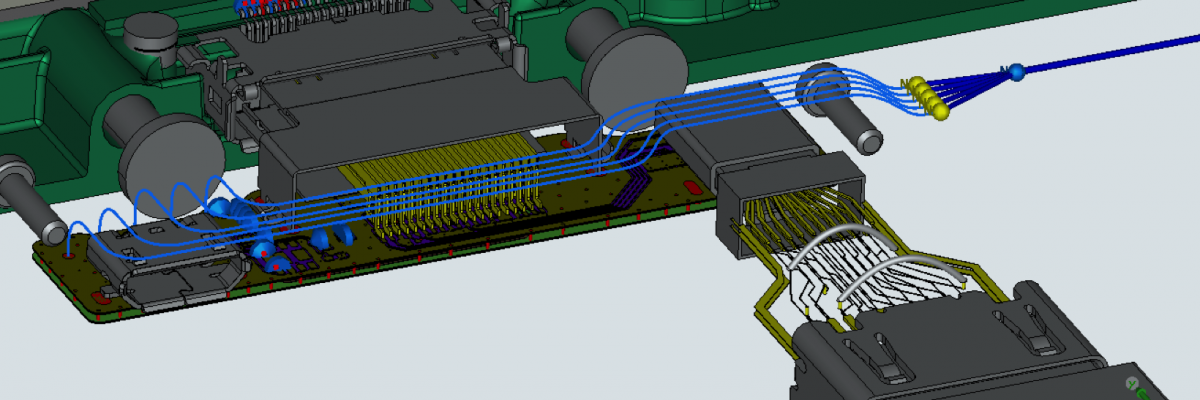

We utilise the most up-to-date tools on the market and we actively develop new methods to improve our efficiency. This means lower costs, better accuracy and faster product development time. At the core of our operations is simulation-assisted design using powerful workstations.

Our secret lies in the methods we have developed – we can simulate how your wireless device will perform at a very early stage of the product development process. Our simulation environment includes comprehensive material, component and macro libraries to facilitate accurate, efficient accurate simulations.

We have developed a custom post-processing tool called UrPo for data analysis and over-the-air estimates. After the concepting work is done, we can use our antenna laboratory and Satimo Starlab for prototyping and design verification.

Convergentia antenna engineers are advanced users of CST Studio Suite, and Optenni simulation tools.

We follow CTIA test plans to align and evaluate devices with head and hand phantoms.

EMC

Electromagnetic compatibility is the ability of a device to work as intended and not to disturb, or be disturbed by, other devices and the surrounding environment.

EMC is an integral and mandatory part of our multidisciplinary design process. Our services are based on our broad, profound, cross-functional understanding of different industries in the EMC field. We want to be present in your design process right from the concepting work. Simulations are added to the design process whenever necessary, and our versatile modules and leading commercial tools mean we can offer a wide range of simulation applications, including shielding and grounding optimisation, radio receiver sensitivity, cross-coupling, PWB design signal integrity, and susceptibility to electrostatic discharge.

Worldwide, there are different official or standards-based requirements that products must meet before they can enter the market. Europe has the CE mark, which means conformity with all the EU directives that the product needs to meet. Using our design and simulation services, your product development does not have to rely on trial and error and measuring several physical prototypes to ensure the conformity of the design. Critical failures can be identified and corrected before the first prototype design is created. The impact on the overall product development cost can be huge.

Our standard EMC design services also cover schematics, layout, module and system design for EMC compliance.

“Critical failures can be identified and corrected before the first prototype design is created. The impact on the overall product development cost can be huge.”

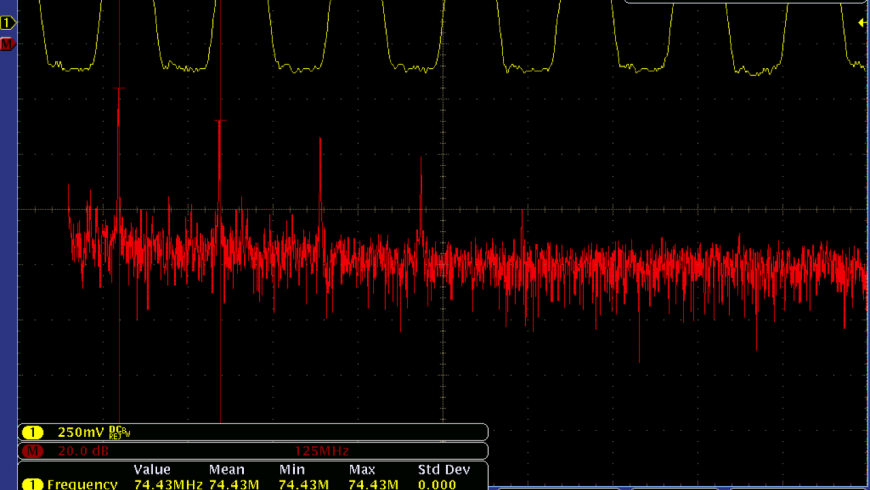

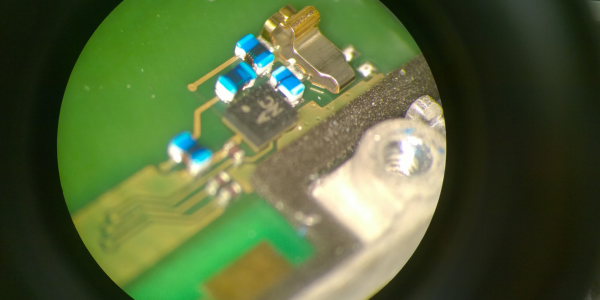

EMC prototyping.

EMC Simulation of Spurious Radiated Emissions in the Case of GSM Transmission – Why and How?

Problem:

Communication through the GSM module created spurious radiated emissions (harmonics) exceeding the maximum allowed level.

Task for the simulation:

Explore the reason for the high level of spurious emissions.

Solution:

The simulations allowed us to deduce that there is a non-linear element in a coupling path that was creating harmonic frequencies. Customer comment: “The process was ideal for our purposes. The solution was found quickly and cost-effectively.”

Mechanics

“Structural mechanics simulations offer a powerful tool to analyse the mechanical performance of devices and to optimise the design to endure extreme conditions and misuse situations.”

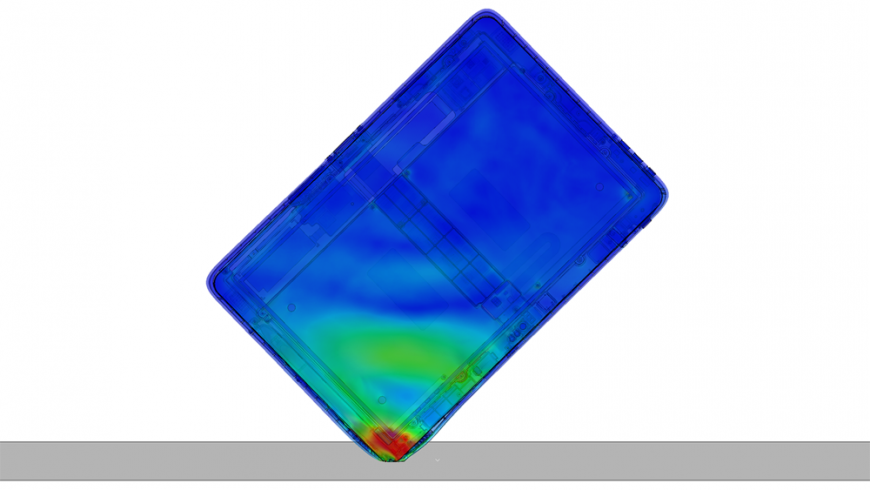

Environmental conditions, different use cases and statutory reliability tests place a wide range of requirements on mechanical structures. There can be all kinds of impacts, including accidental drops and collision with external objects. There can also be dust, moisture or even submerged conditions, vibrations and heat. All of these place tremendous demands on the durability of devices. Structural mechanics simulations offer a powerful tool to analyse mechanical performance and to optimise the design to endure extreme conditions and misuse situations.

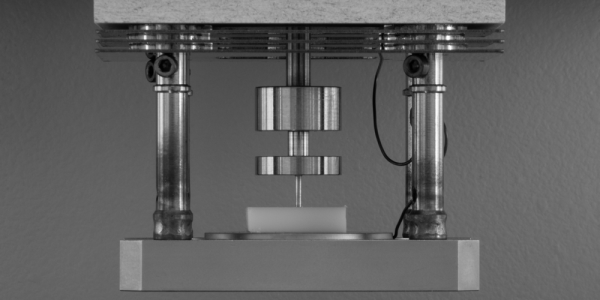

Convergentia’s mechanics team has experience of even the most complex structural mechanics simulations, from large machines to miniature mobile devices. We are experts at modelling complicated material behaviour, multi-part assemblies, complex mechanical interactions and varying load conditions. We use state-of-the-art simulation software from leading software companies, and we have testing tools and methods for developing material models to ensure physically realistic end-to-end structural analysis of your device. Ensure the mechanical quality and robustness of your product by using Convergentia’s virtual proving ground.

Tablet undergoing extreme corner drop test.

Simulation Scenarios

A product’s mechanical requirements can include drop testing, impact testing, ball drops, twisting and bending. Different test scenarios are designed to encompass the probable usage of the device in the field. Why wait until prototypes are available and the often extensive test sequences are completed? Test results only provide a “pass or fail” outcome – they do not offer clear root causes for different failures. Design changes are made based on experience and often based on pure instinct. Even with educated guesses, we still have to wait until new prototypes are ready and tested. Simulations allow product requirements to be taken into account and solutions found at a very early stage – without prototypes. Different design scenarios can be tested virtually in parallel, enabling the best possible mechanical structure within the prevailing conditions.

Simulating Requirements

Wireless equipment is found in a huge variety of applications and environments. Mobile devices are no longer just phones or tablets; they are health measuring instruments, sports devices and devices without human interaction – sometimes just machines talking to each other. New applications and environments are placing increasing demands on the mechanical structures that protect sensitive communication and measuring electronics. The requirements for wireless measuring devices can be extremely harsh: dust, water, heat, impact, vibrations. Smartphones and tablets have found applications in challenging industrial environments. Even consumer devices are advertised with industrial specifications such as IP category, the US military’s MIL-STD-810 standard and the ATEX rating. It is easy to imagine how time-consuming it is to design a rugged, waterproof protective mechanical construction just using experiments. It is much more effective to simulate the environmental conditions, make design modifications, and then verify device conformity through testing.

Material Modelling

Metals, polymers, elastomers, adhesives, composites – all kinds of materials and material combinations are used in mechanical constructions. Do we know how they behave in drop and impact conditions? How stiff and brittle do they become due to high strain rate or at low temperatures? What about the damping characteristics of the elastomer chosen to protect the touch panel or the circuit board? Structural simulations are not just a finite element mesh of mechanical parts with loadings and boundary conditions; physically realistic simulations require material models that can model nonlinear material behaviour completely, including strain rate and temperature effects. Material testing and material modelling capabilities are the backbone of our structural simulation offering.